There is, understandably, significant legislative control relating to industrial radiography. The majority of the requirements are in the Ionising Radiations Regulations 2017, although there are many other statutory provisions for specific types and uses of ionising radiations.

There is, understandably, significant legislative control relating to industrial radiography. The majority of the requirements are in the Ionising Radiations Regulations 2017, although there are many other statutory provisions for specific types and uses of ionising radiations.

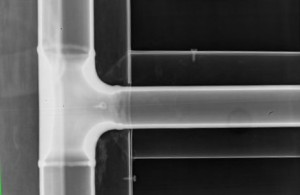

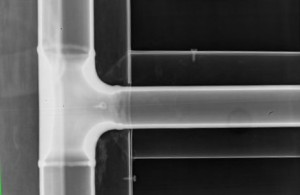

To assure the highest level of safety in all radiography, we will always endeavour to undertake radiography in one of our own custom built laboratories to fully utilise the advanced safety features incorporated in those facilities. Our laboratories continue to receive significant investment as improved radiography system controls are developed.

There are occasions, however, when it is simply not possible to move items for radiography to one of our laboratory facilities and there is no option but to undertake radiography work at the client’s premises. This site radiography must be notified to the Health and Safety Executive (HSE) at least seven days before the work is started, and there is a requirement for Applied Inspection to visit the site to complete a detailed and job specific assessment of how risks associated with the planned radiography will be controlled. These are statutory obligations and we would ask clients to notify Applied Inspection of their requirements at the earliest opportunity to avoid delays in progressing work. Although it is preferable for radiography to be undertaken in our own facilities, we will always work with clients to ensure site radiography is undertaken with the minimum disruption to their normal operations and with a clear concentration on safety and risk control. We understand some clients will not be fully familiar with this advanced form of non-destructive testing and we will take time to explain the process.

There are occasions, however, when it is simply not possible to move items for radiography to one of our laboratory facilities and there is no option but to undertake radiography work at the client’s premises. This site radiography must be notified to the Health and Safety Executive (HSE) at least seven days before the work is started, and there is a requirement for Applied Inspection to visit the site to complete a detailed and job specific assessment of how risks associated with the planned radiography will be controlled. These are statutory obligations and we would ask clients to notify Applied Inspection of their requirements at the earliest opportunity to avoid delays in progressing work. Although it is preferable for radiography to be undertaken in our own facilities, we will always work with clients to ensure site radiography is undertaken with the minimum disruption to their normal operations and with a clear concentration on safety and risk control. We understand some clients will not be fully familiar with this advanced form of non-destructive testing and we will take time to explain the process.

Applied Inspection are licensed to deliver Smith System driver development training. Applied Inspection fully recognises the contribution occupational driving provides to the overall risk profile of the business. The business is committed to ensuring all those required to drive as part of their work have received this training and reflect the businesses commitment to driving safety.

Applied Inspection are licensed to deliver Smith System driver development training. Applied Inspection fully recognises the contribution occupational driving provides to the overall risk profile of the business. The business is committed to ensuring all those required to drive as part of their work have received this training and reflect the businesses commitment to driving safety. There is, understandably, significant legislative control relating to industrial radiography. The majority of the requirements are in the

There is, understandably, significant legislative control relating to industrial radiography. The majority of the requirements are in the  There are occasions, however, when it is simply not possible to move items for radiography to one of our laboratory facilities and there is no option but to undertake radiography work at the client’s premises. This site radiography must be notified to the Health and Safety Executive (HSE) at least seven days before the work is started, and there is a requirement for Applied Inspection to visit the site to complete a detailed and job specific assessment of how risks associated with the planned radiography will be controlled. These are statutory obligations and we would ask clients to notify Applied Inspection of their requirements at the earliest opportunity to avoid delays in progressing work. Although it is preferable for radiography to be undertaken in our own facilities, we will always work with clients to ensure site radiography is undertaken with the minimum disruption to their normal operations and with a clear concentration on safety and risk control. We understand some clients will not be fully familiar with this advanced form of non-destructive testing and we will take time to explain the process.

There are occasions, however, when it is simply not possible to move items for radiography to one of our laboratory facilities and there is no option but to undertake radiography work at the client’s premises. This site radiography must be notified to the Health and Safety Executive (HSE) at least seven days before the work is started, and there is a requirement for Applied Inspection to visit the site to complete a detailed and job specific assessment of how risks associated with the planned radiography will be controlled. These are statutory obligations and we would ask clients to notify Applied Inspection of their requirements at the earliest opportunity to avoid delays in progressing work. Although it is preferable for radiography to be undertaken in our own facilities, we will always work with clients to ensure site radiography is undertaken with the minimum disruption to their normal operations and with a clear concentration on safety and risk control. We understand some clients will not be fully familiar with this advanced form of non-destructive testing and we will take time to explain the process. Hot work is always a high risk activity. Ensuring there is no ignition from that hot work is dependent on correctly preparing the work area and the work piece, and ensuring those undertaking the work and fully competent to understand how those risks are generated and controlled.

Hot work is always a high risk activity. Ensuring there is no ignition from that hot work is dependent on correctly preparing the work area and the work piece, and ensuring those undertaking the work and fully competent to understand how those risks are generated and controlled.