Our technicians are dedicated and experienced personnel, with many certified to PCN, ASNT and ACCP Level III. Many of our senior technicians are known throughout the industry and are recognised as being highly trained, competent individuals who have worked for Applied Inspection for many years.

Our technicians are dedicated and experienced personnel, with many certified to PCN, ASNT and ACCP Level III. Many of our senior technicians are known throughout the industry and are recognised as being highly trained, competent individuals who have worked for Applied Inspection for many years.

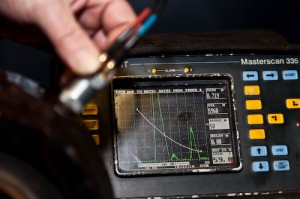

For those unfamiliar with ultrasonic inspection; this type of testing uses sound waves of short wavelength and high frequency to detect flaws or measure material thickness. It is used to test welds, castings and wrought products, e.g. rolled plate or forgings.

Manual testing involves sound waves (pulsed beams of high frequency ultrasound) transmitted via a hand-held transducer, which is placed on the specimen. A ‘couplant’ is used to enable the sound to pass from the transducer to the component under test. Any sound from the pulse that returns to the transducer (echo) is shown on a screen, which gives the amplitude of the pulse and the time taken to return to the transducer. Flaws anywhere through the specimen thickness reflect the sound back to the transducer. Flaw size, distance and reflectivity can be interpreted.

The immersion technique involves placing the component in a tank of water and passing the sound waves through the water into the component. Because of its complexity; considerable technician training and skill is required.

Applied Inspection offer a wide range of training courses in Metallurgy/Materials, Welding and Non-Destructive Testing. Below are examples of the courses we offer – for further information please contact us.

Applied Inspection offer a wide range of training courses in Metallurgy/Materials, Welding and Non-Destructive Testing. Below are examples of the courses we offer – for further information please contact us.

We offer a wide range of metallurgical analysis and materials consultancy; including component failure investigations, warranty claims, metallography, reverse engineering and corrosion investigations. We also offer a collection and delivery service for your convenience.

We offer a wide range of metallurgical analysis and materials consultancy; including component failure investigations, warranty claims, metallography, reverse engineering and corrosion investigations. We also offer a collection and delivery service for your convenience.

Our laboratories are headed by experienced and knowledgable personnel with the commitment to provide our customers with a radiographic service second to none. We deliver a flexible service with quick turnaround times; working to support the most pressurised production schedules.

Our laboratories are headed by experienced and knowledgable personnel with the commitment to provide our customers with a radiographic service second to none. We deliver a flexible service with quick turnaround times; working to support the most pressurised production schedules.

Applied Inspection provide a professional and comprehensive welding and welder training service throughout the UK. Our welding staff are experienced in all processes and material types, offering a service to suit your business needs. We also provide weld repairs and coordination services/welding engineering consultancy. Our welding facility based in Burton Upon Trent houses the latest technology.

Applied Inspection provide a professional and comprehensive welding and welder training service throughout the UK. Our welding staff are experienced in all processes and material types, offering a service to suit your business needs. We also provide weld repairs and coordination services/welding engineering consultancy. Our welding facility based in Burton Upon Trent houses the latest technology.